If you’ve ever wondered how modern print-on-demand brands create such soft, vibrant, hyper-detailed prints, the answer is almost always: DTG — Direct-to-Garment.

From kawaii anime tees to pastel chibi hoodies, DTG has become the top-choice printing method for creators, POD sellers, and apparel brands worldwide. And for platforms like Printeby, where every chibi line and every gradient matters, DTG is not just a printing method — it is the heart of product quality.

At Printeby, every chibi shirt is printed using DTG technology to preserve every stroke, every soft blush tone, and every tiny expression. DTG allows us to recreate adorable artwork exactly as it was drawn — smooth, vibrant, and full of emotion.”

1. What Is DTG Printing?

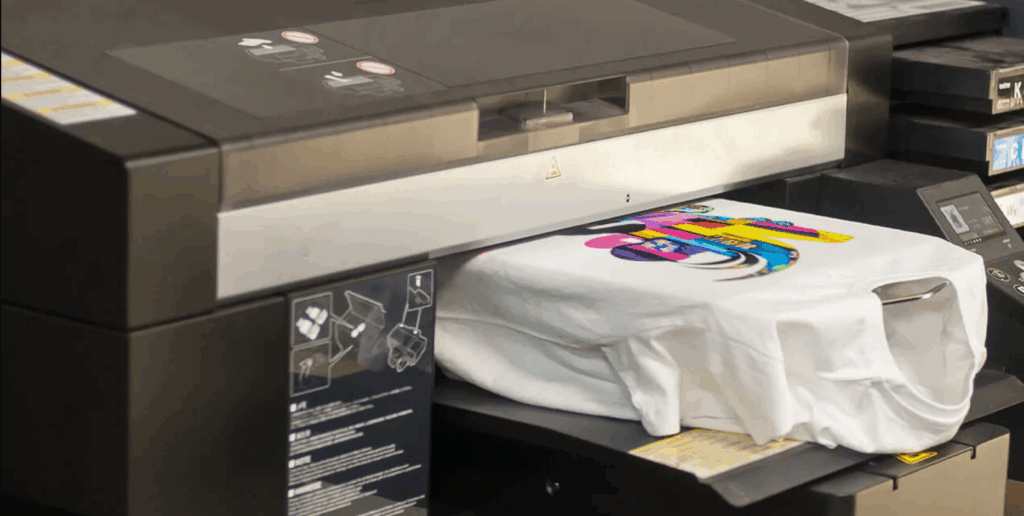

DTG (Direct-to-Garment) is a modern printing method where a digital printer sprays water-based ink directly onto fabric fibers — similar to an inkjet printer, but engineered for apparel.

Unlike traditional screen printing, which requires creating screens for each color, DTG allows you to print full-color, high-detail artwork without limitations.

Why DTG became the #1 printing method for anime and chibi merchandise

- It captures subtle gradients

- It prints soft pastel shading

- It reproduces tiny facial details

- It preserves smoothing, highlights, textures

Exactly the style you see across Printeby’s most loved products:

- Tee: https://printeby.com/unisex/t-shirt-unisex/lets-go-chibi-unisex-softstyle-t-shirt/

- Garment-Dyed Tee: https://printeby.com/unisex/watch-out-for-furballs-chibi-unisex-garment-dyed-heavyweight-cotton-tee/

- Unisex Chibi Sweatshirt: https://printeby.com/unisex/watch-out-for-furballs-chibi-unisex-french-terry-raglan-crewneck/

2. How Does DTG Printing Work?

Professional DTG factories follow a 4-step workflow:

2.1.Pre-treatment (For Dark Fabrics)

A layer of pre-treat solution is sprayed onto the garment.

This step helps:

- White underbase adhere to fabric

- Prevent ink bleeding

- Enhance color vibrancy

Important for black, navy, maroon, forest, or any mid-to-dark colors.

2.2 Heat Pressing the Pre-treated Shirt

The shirt is pressed for 10–20 seconds to flatten fibers and “seal” the pre-treat.

3.3 Direct Printing

The printer sprays ink using up to 6–8 channels:

- CMYK (color)

- White (underbase for dark garments)

Software used (e.g., Kothari RIP, Epson Garment Creator) controls:

- Saturation

- Dot placement

- Underbase thickness

- Color reproduction accuracy

The artwork prints line by line, just like a high-resolution inkjet graphic.

4.4 Final Curing (Heat Press / Tunnel Dryer)

Ink is cured at 120–160°C for 60–180 seconds, depending on ink brand.

Result:

A soft, flexible, breathable print that feels like it’s part of the fabric.

3. Advantages of DTG Printing

3.1. Perfect for Complex Artwork (Chibi, Anime, Digital Art)

DTG handles:

- Soft gradients

- Shading

- Kawaii cheeks

- Tiny details like eyelashes

- Multicolor characters

This is why Printeby heavily relies on DTG across its catalogue.

3.2. Unlimited Colors (Cost-Effective for Small Runs)

Whether your artwork has 5 colors or 500, the cost is the same.

No screens, no color setup — fully digital.

3.3. Soft-Touch Print (Feels Like Part of the Fabric)

Unlike DTF or vinyl, DTG does not create a plastic layer.

The print is soft, breathable, and lasts through 45–60 washes.

3.4. Ideal for Print-on-Demand (POD)

DTG allows:

- Single-piece printing

- Zero inventory

- Fast turnaround

- Personalized orders

Exactly the foundation of the Printeby production model.

Create your own DTG-printed merch here:

https://printeby.com/create-your-own/

3.5. Eco-Friendly & Sustainable

- Water-based ink

- Low chemical waste

- Print-on-demand reduces overproduction

A perfect match for eco-driven brands.

4. Disadvantages of DTG Printing

DTG is powerful — but not perfect.

4.1. Works Best on Cotton

The more polyester in a garment, the more the colors may fade or dull.

4.2. Dark Shirts Require Pre-treatment

Without proper pre-treat:

- Colors may look muted

- White underbase may appear grainy

- Stains (pre-treat marks) may show temporarily

4.3. Higher Cost than Screen Printing for Bulk Orders

For 100–10,000 units → screen printing becomes more economical.

4.4. Not Ideal for Ultra-Stretch Fabrics

Spandex, swimwear, and athletic wear do not hold DTG ink well.

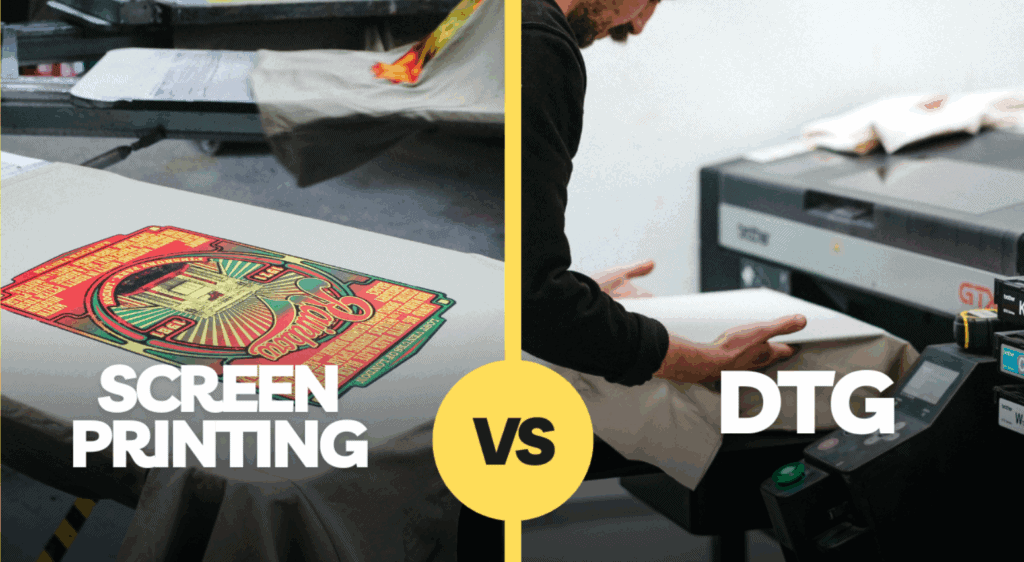

5. DTG vs. Screen Printing

| Feature | DTG | Screen Printing |

|---|---|---|

| Best For | Small batches, complex art | Bulk orders, simple graphics |

| Color Limits | Unlimited | Limited, cost per color |

| Detail | Excellent | Good for bold designs |

| Feel | Very soft | Slightly thicker |

| Setup Cost | Almost none | High |

| Speed | Slower per unit | Very fast for bulk |

If your design has anime, shading, gradients, K-art, or chibi — DTG wins.

6. Best Fabrics for DTG Printing

Best Choices

1. 100% Ring-Spun Cotton

The absolute best for vibrancy & softness.

This is the type used in most Printeby products.

Examples:

2. Cotton-Rich Blends (80/20)

Colors slightly less intense but still good.

Acceptable (But Not Ideal)

- 60/40 cotton/poly

- Heather blends

Not Recommended

- 100% polyester

- Nylon

- Spandex

- Fleece with heavy lint

7. Professional DTG Design Tips (Make Your Prints Look Perfect)

These are the same guidelines pro POD sellers use.

7.1. Use High-Resolution Files (4500 × 5400 px, 300 DPI)

Standard POD dimension.

7.2. Export in sRGB IEC61966–2.1

The color standard used by most RIPs.

7.3. Increase Contrast & Vibrance Slightly

DTG ink absorbs into fibers → colors naturally soften.

7.4. For Black Shirts: Use Light Outlines

Helps characters stand out, especially kawaii/chibi art.

7.5. Avoid Ultra-Thin Lines (<1 px)

They may disappear during printing.

7.6. Remove Background Unless Necessary

Transparent PNG for cleaner output.

8. Common DTG Problems (and How to Fix Them)

Faded Colors on Dark Fabric

Cause: weak underbase

Fix: increase white ink layer

Sticky Feel After Printing

Cause: under-curing

Fix: longer heat press / tunnel dryer cycle

Fibers Visible Through Print

Cause: garment not pre-pressed

Fix: flatten fabric before printing

White Spots / Speckles

Cause: lint on shirt

Fix: lint-roll before printing

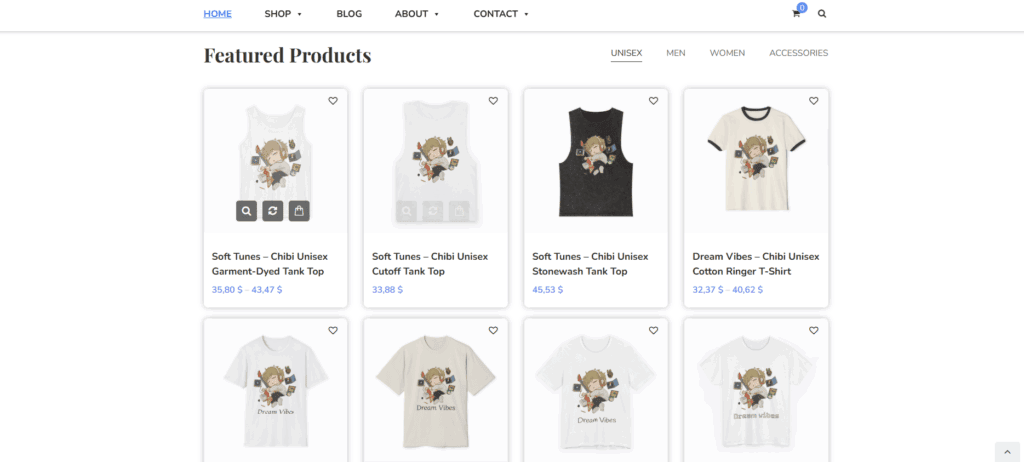

9. DTG in POD: Real Case Study From Printeby

Printeby is built around a 100% made-to-order model.

Each product is printed only when a customer buys it.

Using DTG allows Printeby to:

Reproduce detailed chibi artwork

Every blush, highlight, sparkle, and pastel gradient is preserved.

Print unlimited colors without extra cost

Perfect for anime & K-art illustration.

Offer 1-piece personalization

Customers can order:

- A single custom tee

- One personalized hoodie

- One unique gift

✔ Maintain sustainability

No overstock. No waste.

Only printing what is truly needed.

Keep products soft, breathable, and durable

A requirement for kidswear & casual wear.

Explore Printeby’s full DTG product list:

https://printeby.com/shop/

10. FAQ – Frequently Asked Questions

Q1. Does DTG last long?

Yes — 45 to 60 washes with proper care.

Q2. Does DTG crack?

Usually no.

DTG sinks into fibers, not sitting on top like DTF.

Q3. Is DTG good for black shirts?

Yes, but only with proper pre-treatment and underbase.

Q4. Can DTG print neon or metallic ink?

No — for those effects, use screen printing or DTF specialty inks.

Q5. Which is better: DTG or DTF?

- DTG → softer, breathable, best for cotton

- DTF → better for polyester, more durable but thicker feel

Q6. Can I print photos?

Absolutely. DTG excels at photo-realistic prints.

Q7. Is DTG eco-friendly?

Yes — water-based inks + no overproduction.

11. Final Thoughts

DTG printing has become the gold standard for high-quality apparel printing — especially for creators, anime lovers, and chibi artists who want every detail to shine.

Whether you’re launching a new clothing line, selling print-on-demand merch, or creating personalized gifts, DTG offers the perfect mix of:

- Vibrancy

- Detail

- Soft feel

- Sustainability

- Flexibility

At Printeby, DTG printing is how we bring chibi emotions to life — on tees, hoodies, tumblers, notebooks, and more.

Explore Printeby’s full DTG product catalog:

https://printeby.com/shop/